-

K-TEC170 Txheem Yas Txhaj Moulding Tshuab

● Tag Nrho Cov Qauv Tsim Muaj Kev Nyab Xeeb Siab

● Qhov chaw loj dua nruab nrab ntawm Tie-Bars Zoo dua adaptability● Modern Control Technology, ntiaj teb nto moo hom maub los

ceev teb ceev, yooj yim rau kev khiav hauj lwm● Precision Clamping Unit, Txais 5 ntsiab lus lub luj tshib thiab hydraulicmechanical tsav tshuab -

K-TEC170 Txheem Yas Txhaj Moulding Tshuab

● Tag Nrho Cov Qauv Tsim Muaj Kev Nyab Xeeb Siab

● Qhov chaw loj dua nruab nrab ntawm Tie-Bars Zoo dua adaptability● Modern Control Technology, ntiaj teb nto moo hom maub los

ceev teb ceev, yooj yim rau kev khiav hauj lwm● Precision Clamping Unit, Txais 5 ntsiab lus lub luj tshib thiab hydraulicmechanical tsav tshuab -

Phoenix-230P Ib nrab Kev Kub Ceev Yas Txhaj Moulding Tshuab

Piv nrog rau cov tshuaj txhaj tshuaj molding tshuab, Phoenix / P series muaj kev txhaj tshuaj sai, uas tuaj yeem ncav cuag li 150mm / s.Nws tuaj yeem daws qee qhov tsis xws ntawm cov tshuaj txhaj tshuaj molding tshuab hauv cov txheej txheem txhaj tshuaj (xws li dej ripples, thiab lwm yam);

Ua tau raws li cov neeg siv khoom xav tau siab rau qhov precision;

Nrog finite element technical analysis platen tsim, optimizing platen qauv, nplooj siab rau ceev ceev, tshwj xeeb tshaj yog haum rau precision pwm siv;

Txais kev tsim qauv, tib lub pwm xauv lub tshuab tuaj yeem ua ke nrog cov kev qhia tshwj xeeb ntawm kev txhaj tshuaj thiab cov ntsia hlau;

Piv nrog rau cov tshuaj txhaj tshuaj molding tshuab, nws muaj zog tso zis ntau dua.

-

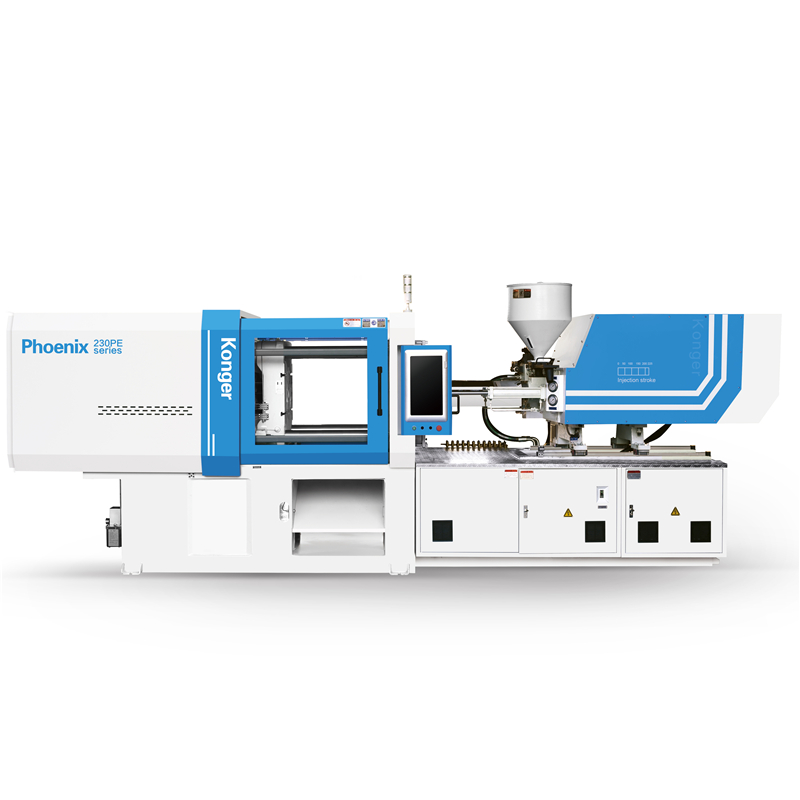

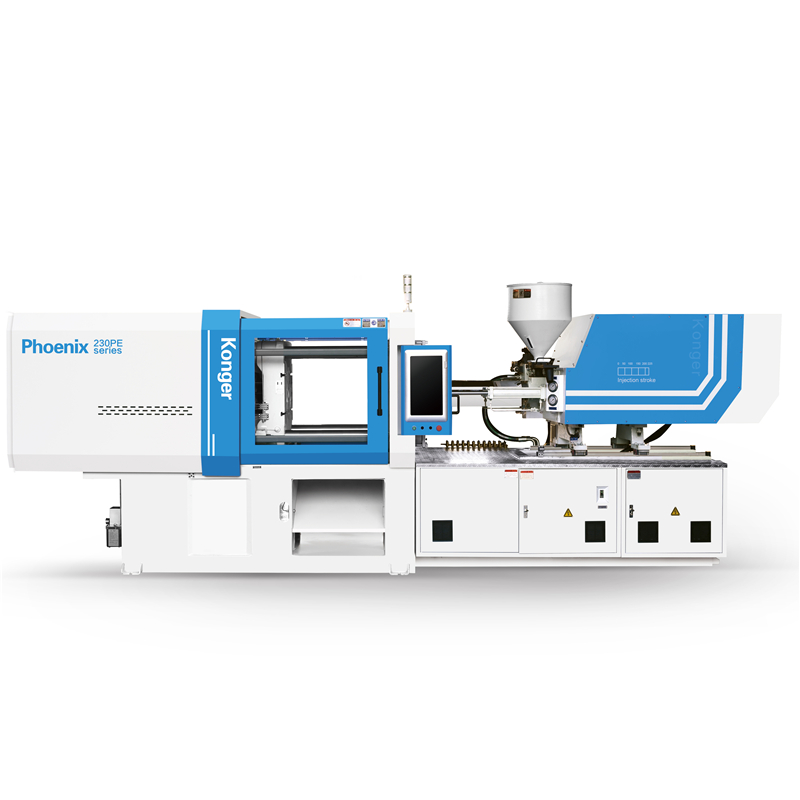

Phoenix-230PE Ib nrab Kev Kub Ceev Yas Txhaj Moulding Tshuab Nrog Hluav Taws Xob

Piv nrog rau cov tshuaj txhaj tshuaj molding tshuab, Phoenix / P series muaj kev txhaj tshuaj sai, uas tuaj yeem ncav cuag li 150mm / s.Nws tuaj yeem daws qee qhov tsis xws ntawm cov tshuaj txhaj tshuaj molding tshuab hauv cov txheej txheem txhaj tshuaj (xws li dej ripples, thiab lwm yam);

Ua tau raws li cov neeg siv khoom xav tau siab rau qhov precision;

Nrog finite element technical analysis platen tsim, optimizing platen qauv, nplooj siab rau ceev ceev, tshwj xeeb tshaj yog haum rau precision pwm siv;

Txais kev tsim qauv, tib lub pwm xauv lub tshuab tuaj yeem ua ke nrog cov kev qhia tshwj xeeb ntawm kev txhaj tshuaj thiab cov ntsia hlau;

Piv nrog rau cov tshuaj txhaj tshuaj molding tshuab, nws muaj zog tso zis ntau dua.

-

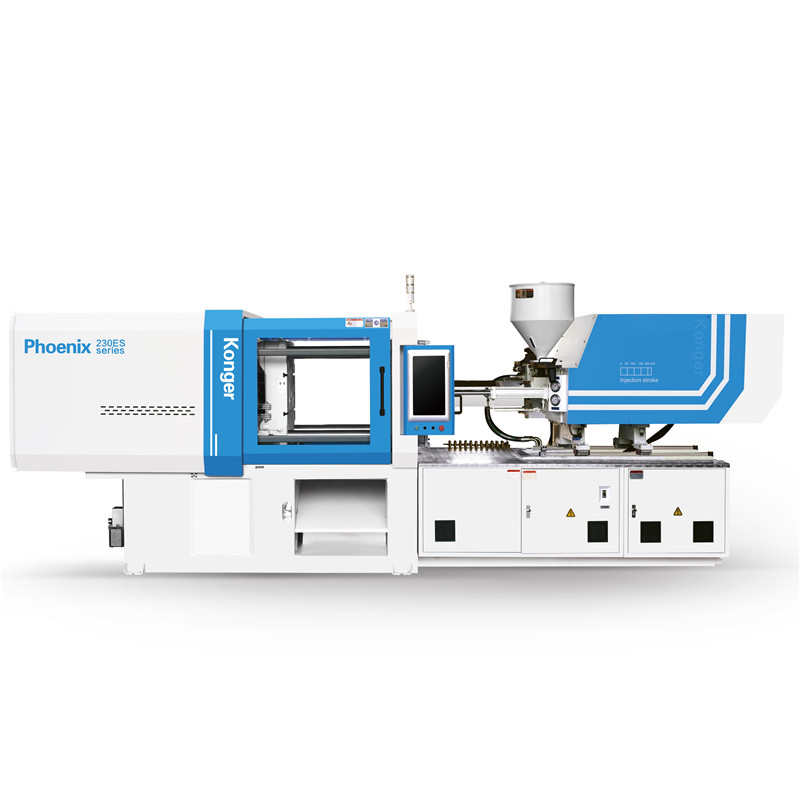

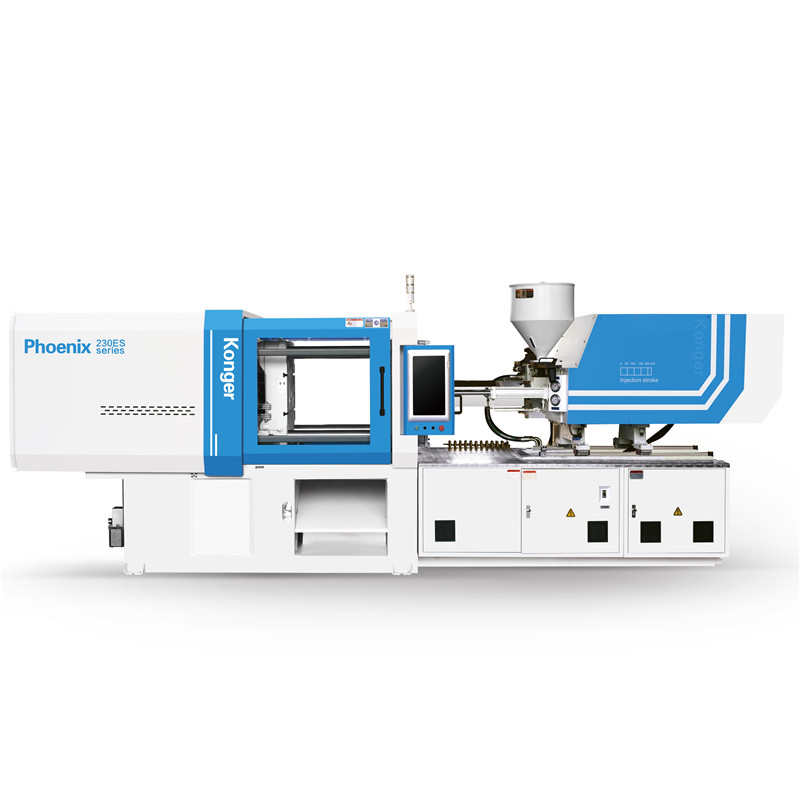

Phoenix-230ES Tag Nrho Kev Kub Ceev Yas Txhaj Moulding Tshuab

Lub tshuab txhaj tshuaj yog tag nrho cov hluav taws xob, thiab kev txhaj tshuaj ceev tuaj yeem ncav cuag 300-1000mm / s; Cov khoom khaws cia tau txais cov lus teb siab, lowinertial servo lub cev muaj zog nrog siv lub log tsav ntsia hlau qauv, Tsis tsuas yog tuaj yeem txhim kho qhov tseeb, tab sis kuj txuag hluav taws xob.Nws tuaj yeem ua tiav kev ua haujlwm sib xyaw ua ke, ua kom luv lub voj voog molding;

Nrog finite element technical analysis platen tsim, optimizing platen qauv, nplooj siab rau ceev ceev, tshwj xeeb tshaj yog haum rau precision pwm siv;

Txais kev tsim qauv qauv, tib lub pwm xauv lub tshuab tuaj yeem ua ke nrog cov kev qhia tshwj xeeb ntawm kev txhaj tshuaj thiab cov ntsia hlau.

-

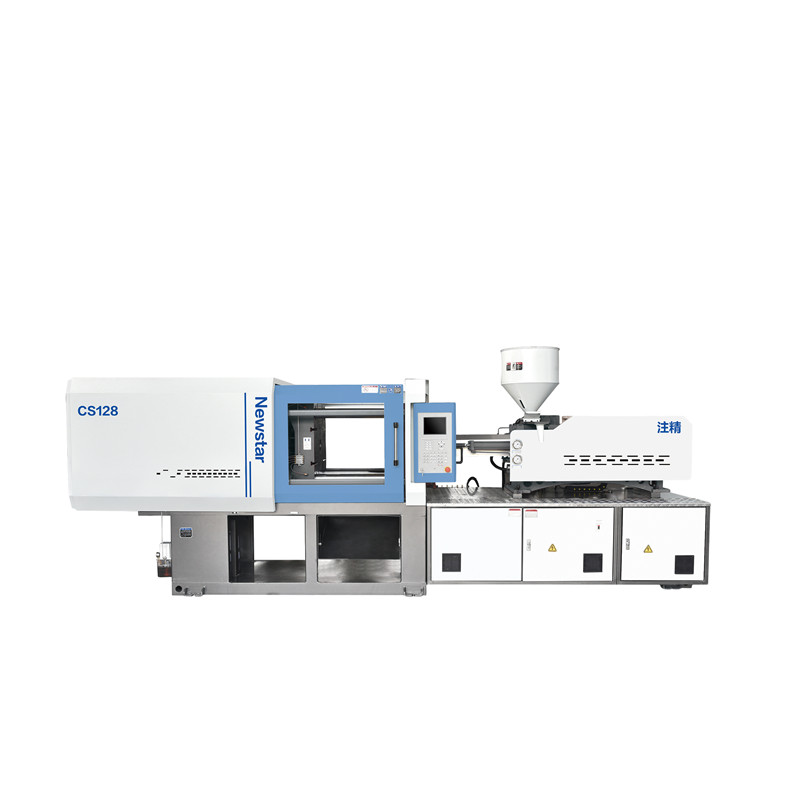

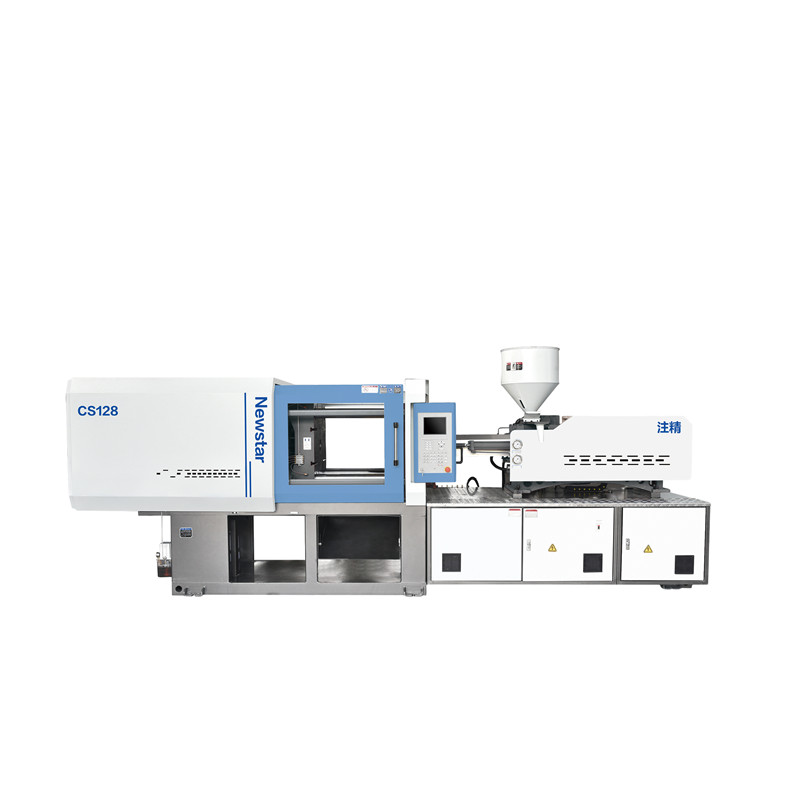

Newstar Series Yas Txhaj Molding Tshuab

Zoo molding tsim valvestability

Lub servo tsav tsheb muaj nws lub siab thiab ntws nyob rau hauv kaw lub voj tswj: thiab piv nrog cov tshuaj txhaj molders, nws molding repetition precision yog zoo dua.Teb ceev ceev

Tus neeg tsav tsheb servo muaj cov lus teb ceev ceev uas nws lub sijhawm pib sai tau txhim kho los ntawm 50% piv nrog cov tshuaj txhaj tshuajKev ua haujlwm siabV kev tiv thaiv ib puag ncig

Lub tshuab ua tiav cov yam ntxwv, tsis tshua muaj suab nrov, thiab txawm tias ntsiag to thaum lub sijhawm ua haujlwm qis -

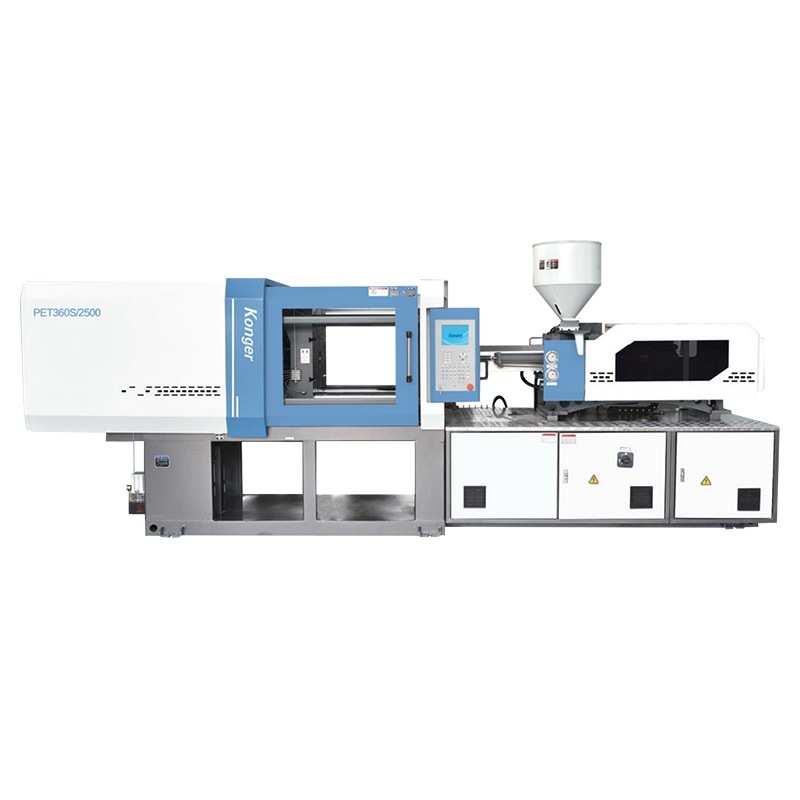

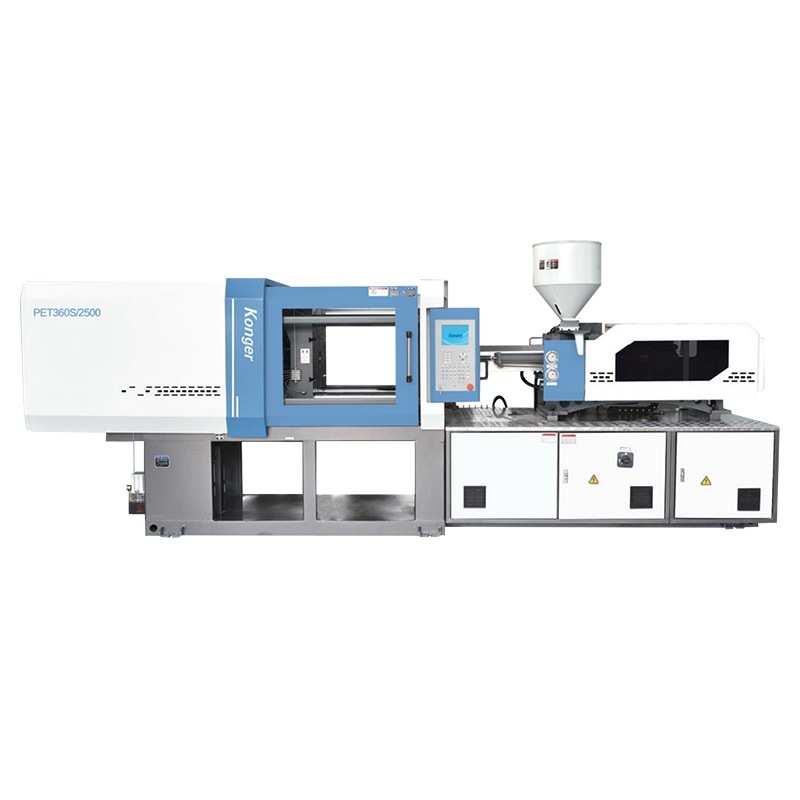

PET Series Yas Txhaj Moulding Tshuab

● Tshwj xeeb ntawm PET ntsia hlau thiab chim.Txhim kho tus nqi ceev thiab txhaj tshuaj hnyav.Txo cov plasticizing kub thiab AA.Txhim kho qhov kev cog lus ntawm lub raj mis zoo thiab txhim kho qhov pom tseeb.

● Lub twj tso kua mis sib txawv tuaj yeem txuag tau 25%–45% lub zog dua li kho lub twj tso kua mis.Servo cov cav tov tuaj yeem txuag tau 30%–50% lub zog dua li kho lub twj tso kua mis.

● Ntau lub tshuab ua qauv sib txawv ntawm qhov sib txawv ntawm lub raj mis.Qhov hnyav maxinjection: 5000 grams.Muaj zog eject quab yuam thiab eject stroke tshwj xeeb rau lub raj mis PET.

-

Chameleon-CMS Series Yas Txhaj Moulding Tshuab

● Reciprocating 180 degree kev sib hloov lub rooj ntawm lub phaj txav.tuaj yeem teeb tsa ob lub pwm tsim ob yam khoom sib txawv.

● Ib lub tog raj kheej txhaj tshuaj kom txhaj tshuaj ruaj khov thiab raug.

-

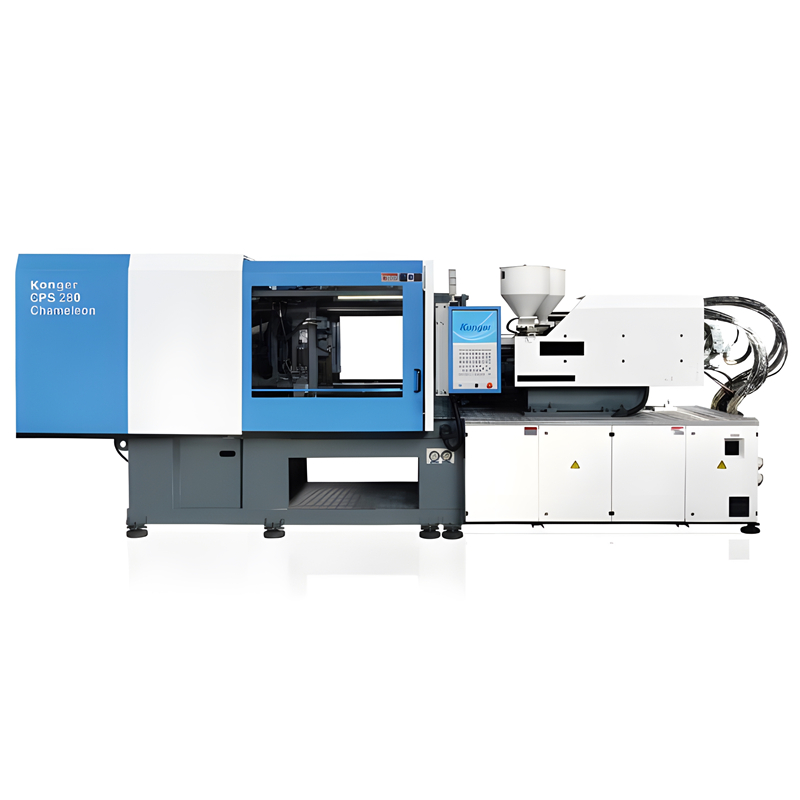

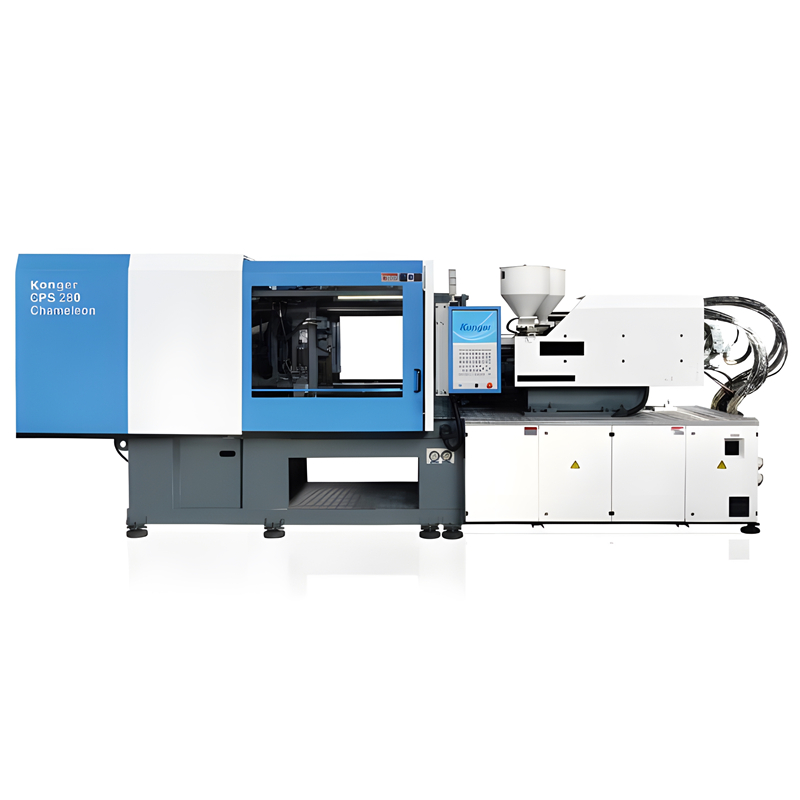

Chameleon-CPS Series Yas Txhaj Moulding Tshuab

● Ua haujlwm zoo Servo Iav kis qauv kom tig kev kub ceev nrog txoj haujlwm ruaj khov thiab meej.

● Graphite tooj liab tes tsho siv rau khi-bar thiab eject qhia bar.Graphite tooj liab thaiv pads siv rau ntawm lub phaj txav thiab phaj kawg kom ceev thiab meej pwm qhib txoj hauj lwm.

-

Bakelite Series Yas Txhaj Moulding Tshuab

● Tshwj xeeb tsim ntsia hlau & chim rau Bakelite, uas yog ua tiav los ntawm siab zog bi-metalli steel nrog cov yam ntxwv ntawm anticorrosion andabradability.

● Siv cov cuab yeej oilcoling, txhawm rau kom paub tseeb tias qhov tseeb & ruaj khov ntawm kev tswj qhov kub thiab txias.

● Cov khoom siv plasticity zoo heev xws li cov bakelites, tawg cov pwm thiab tso pa tawm.

● Hloov cov ntsia hlau & chim, tuaj yeem hloov mus rau hauv thermoplasticity txhaj tshuaj molding tshuab.

-

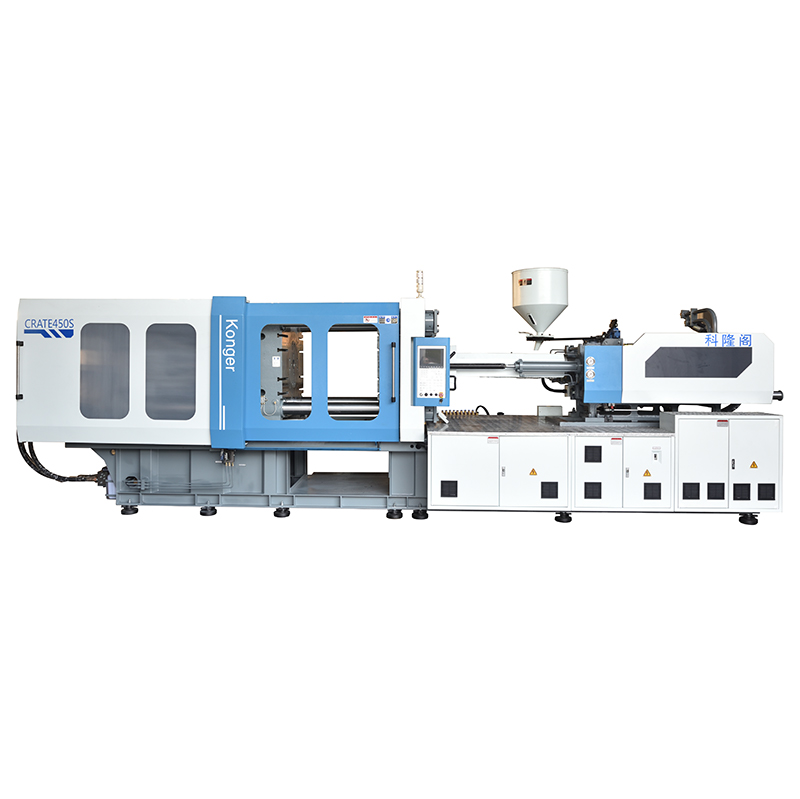

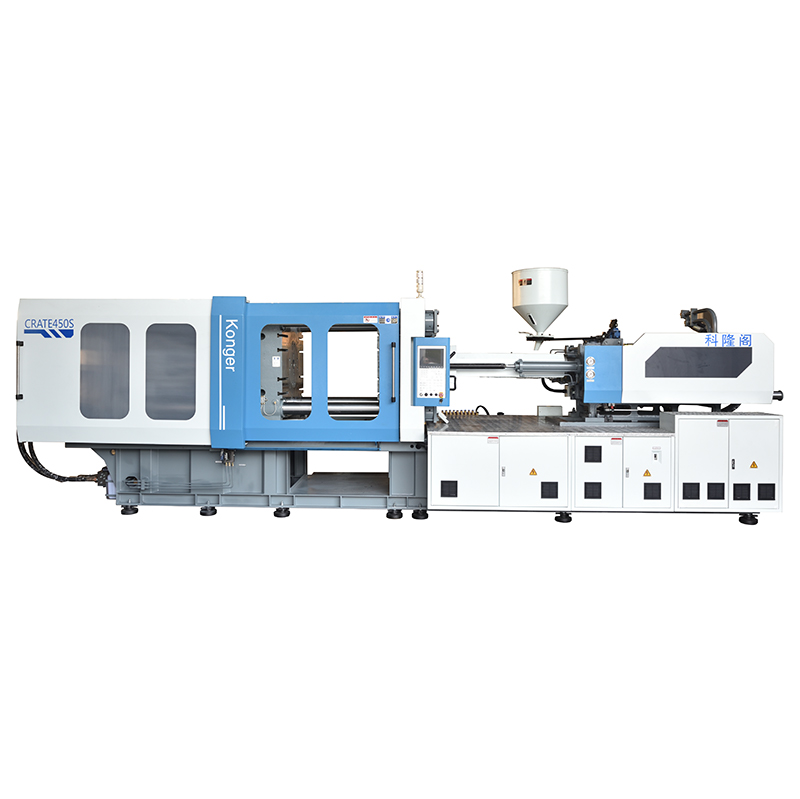

Crate-Servo Tsav Series Yas Txhaj Moulding Tshuab

High-speed clamping tsev

Lub cev muaj zog tsis siv neeg clamping tsev siv Gear-rack tsav, tshiab tsim pwm kaw cov khoom los ntawm lub computer simulation technology.Thiab ua kom lub hardening tsom xam ntawm tag nrho cov Cheebtsam, optimized internal stress & variable hom, thiaj li hais tias lub tshuab txav ntau stability thiab smoothly thaum nws khiav nrog kev kub ceev.Nws yog qhov zoo kom tsis txhob tawg rau lub phaj thiab khi-bar los ntawm lub zog siab & tsis tshua muaj kev ntxhov siab.

Exelent muaj nuj nqi & lub zog txuag

Konger Crate Series ntawm lub tshuab kev tshaj lij siv cov tshuab servo tuaj txawv teb chaws raws li lub zog hluav taws xob, uas muaj kev ua haujlwm zoo tshaj plaws, tuaj yeem txuag tau 20% -40% lub zog thiab 5% -10% zog piv nrog cov tsoos kho twj tso kua mis Circulation Box tshuab ua haujlwm zoo dua.

-

Crate-Standard Pump Series Yas Txhaj Moulding Tshuab

High-speed forming tshuab

Lub koos pij tawj tswj nrog lub twj tso kua mis muaj zog thiab servo system ruaj khov thiab nrawm dua li lwm tus.Nws tuaj yeem txo lub sijhawm txhaj tshuaj molding ntawm 15-20%.

Electronic Control Unit

Konger siv cov maub los nrog cov khoom siv high-end kev txhaj tshuaj molding tshuab, nws muaj lub ntsej muag zoo nkauj nrog qhov loj me thiab ua rau peb xis nyob.Tsis tas li ntawd, Konger siv cov khoom siv hluav taws xob tseem ceeb nrog lub npe nrov, xws li: Schneider, Omron, Siemens, thiab lwm yam.Lawv muaj ntau ruaj khov zoo thiab txhim khu kev qha muaj nuj nqi, nws cov txiaj ntsig los lav ib txwm ua haujlwm ntawm chav tswj hluav taws xob.