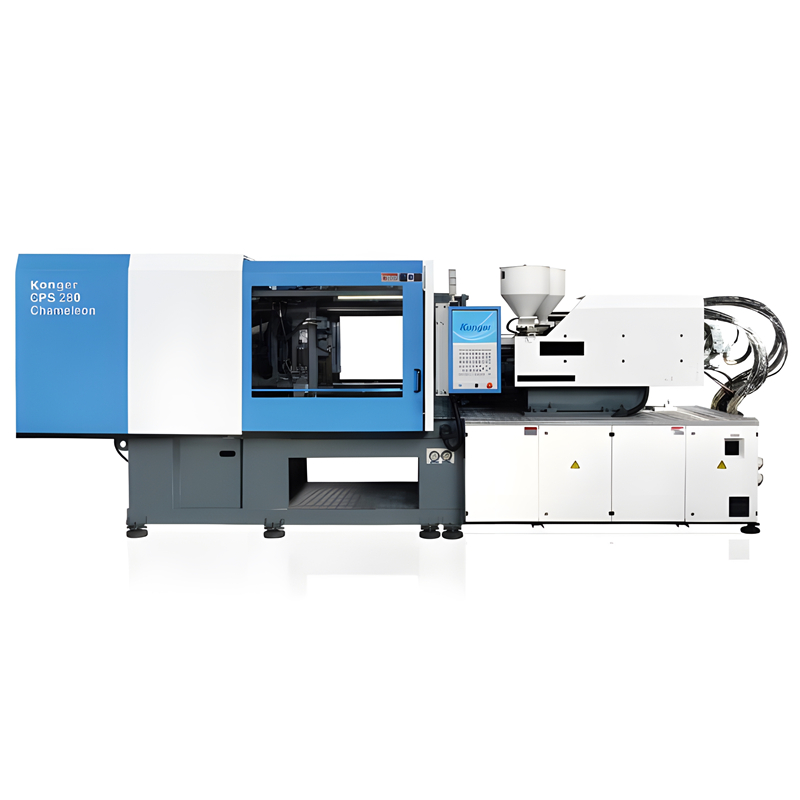

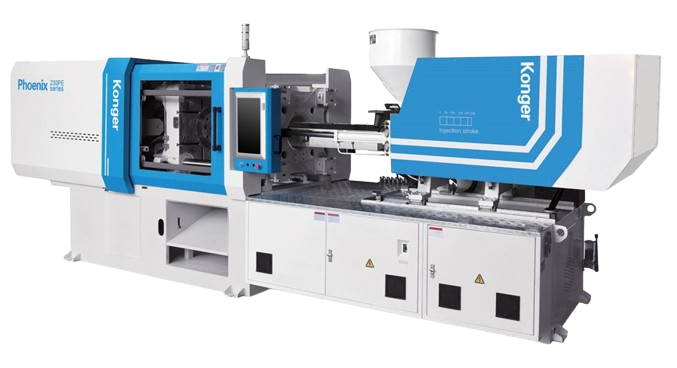

Phoenix-230ES Tag Nrho Kev Kub Ceev Yas Txhaj Moulding Tshuab

Phoenix-230ES Tag Nrho Kev Kub Ceev Yas Txhaj Moulding Tshuab

Cov khoom zoo

Ningbo Konger Machinery Co., Ltd. yog nyob rau hauv Ningbo City ntawm Tuam Tshoj (nws lub npe hu ua "lub captical ntawm Txhaj Moulding Tshuab" & "qhov chaw nres nkoj loj tshaj plaws nyob rau hauv lub ntiaj teb no"), uas yog ib tug high-tech enterprise, tsom rau txoj kev loj hlob. , ntau lawm, kev muag khoom thiab kev pabcuam tshwj xeeb txhaj tshuaj molding tshuab. Nws tau dav siv hauv qhov chaw pib, cov khoom ua si, khoom siv txhua hnub, hluav taws xob, kev kho mob,

ntim, siv cov khoom siv alogistics, thiab lwm yam kev lag luam ntau tus txheeb ze cov khoom lag luam.

Txog tam sim no, Konger muaj kev koom tes sib sib zog nqus nrog ntau lub tuam txhab hauv tsev thiab txawv teb chaws hauv qhov project lossis kev ua haujlwm. Konger tau tsim ib qho kev pabcuam tiav thiab kev sib txuas lus thiab tsim cov banchs thiab cov neeg sawv cev, xws li Shanghai, Guangzhou, Taizhou, thiab lwm lub nroog ntawm Tuam Tshoj. Dhau li ntawd, tau teeb tsa cov neeg xa khoom lossis cov neeg sawv cev hauv Is Nrias teb, Nyab Laj, Qaib Cov Txwv, Indonesia, thiab tshaj nees nkaum lwm

suav teb. Peb tab tom ua "Konger" hom txhaj tshuaj molding tshuab nrov hauv Suav teb thiab paub thoob plaws ntiaj teb.

Phoenix ib lub tog raj kheej ceev ceev series

Piv nrog rau cov tshuaj txhaj tshuaj molding tshuab, Phoenix / P muaj kev txhaj tshuaj sai, txog li 150mm / s, uas tuaj yeem daws qee qhov tsis xws luag hauv cov txheej txheem txhaj tshuaj ntawm cov tshuaj txhaj tshuaj molding tshuab (xws li dej ripples);

Yuav ua tau raws li cov kev xav tau siab ntawm cov neeg siv khoom rau precision qhov ntau lawm;

Finite element kev nyuaj siab tsom xam template tsim, optimize tus qauv qauv, tshwj xeeb rau kev khiav ceev, tshwj xeeb tshaj yog rau precision pwm siv;

Modular tsim, tib lub ntsuas phoo mechanism tuaj yeem ua ke nrog cov kev qhia tshwj xeeb ntawm kev txhaj tshuaj thiab cov ntsia hlau;

Piv nrog rau cov tsoos txhaj tshuaj molding tshuab, nws muaj ntau zog tso zis ntau lawm.

● Lub Phoenix series zoo kawg nkaus ua ke hluav taws xob thiab hydralalic system. Lub Modular Tsim kuj tuaj yeem ua tiav kev txav txav synchronization. Yog li ntawd, kev ua haujlwm siab ntawm lub tshuab ua rau nws muaj kev sib tw ntau dua hauv kev ua lag luam.

● Lub tshuab nrog cov tshuaj tiv thaiv zoo, kev kub ceev, cov lus teb siab, nws tuaj yeem ua tiav ntau qhov kev ua haujlwm ib txhij thiab txhim kho kev tsim khoom.

● Optimized tshuab toggle qauv, qhib thiab kaw pwm yog du thiab ceev, thiab lub neej ua haujlwm ntev dua.

● Txhim khu kev tua phom, ntsia hlau nrog kev tsim kho plasticization, high-precision, kaw-voj ntsuas kub tswj.

Product Description

1

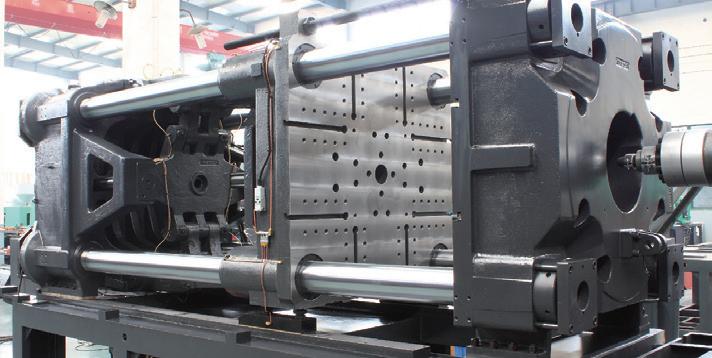

CLAMPING PART

● Lub Tie-Bars nto siv tawv chrome kev kho mob, nws yog hnav-resistant thiab anticorrosion.

● Nrog finite element technical analysis platen tsim, optimizing cov qauv platen, txo cov deformation thiab tawg ntawm platen, txhim kho qhov precision ntawm clamping, thiab txo pwm poob.

● Tsis siv neeg centralizing lubrication system, txo cov nqi tu.

● Sgchronous iav pwm hloov, paub nws pib pwm kho.

● Optimized tshuab toggle qauv, qhib thiab kaw pwm yog du thiab ceev, thiab lub neej ua haujlwm ntev dua.

2

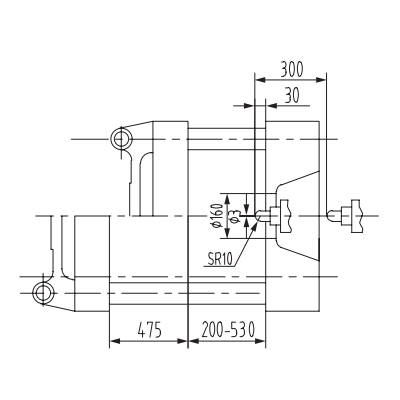

INJECTION UNIT

● Kev txhaj tshuaj ib leeg-lub tog raj kheej tshwj xeeb, kev daws cov phenolmenon ntawm ib lub tog raj kheej roj to hauv kev ua lag luam, txhim kho kev txhaj tshuaj raug thiab kev txhaj tshuaj synchronization.

● Optimized ntsia hlau tsim, haum rau ntau yam ntawm raw cov ntaub ntawv, ntau yam ntsia hlau configurations kom tau raws li cov kev xav tau ntawm cov khoom sib txawv.

● Ua kom lub zog muaj zog, tag nrho lub tshuab ua kom nrawm dua, kev txhaj tshuaj nrawm yog li 150mm / s.

● Lub tshuab txhaj tshuaj tuaj yeem ntsia tau rau lub pob ntsia hlau kom paub qhov kev txhaj tshuaj hluav taws xob tag nrho, qhov kev txhaj tshuaj nrawm tuaj yeem ncav cuag 300-1000mm / s.

3

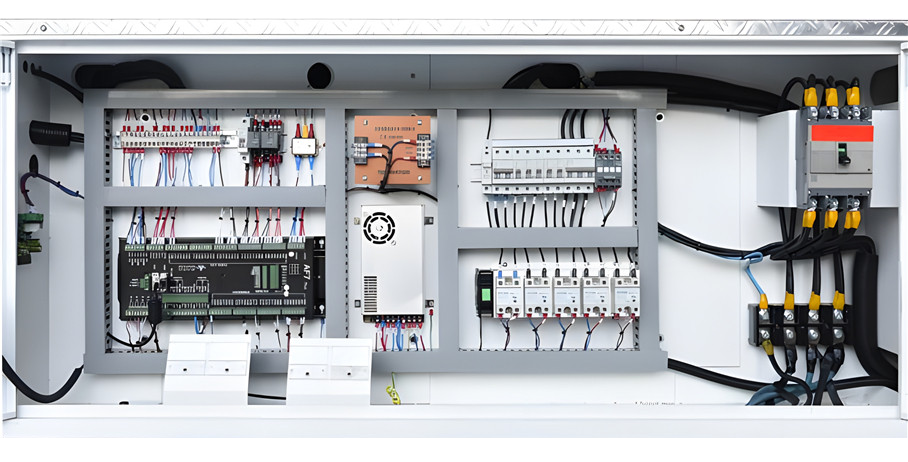

ELECTRIC SYSTEM

● Tus maub los txais yuav lub computer tshwj xeeb ntawm kev txhaj tshuaj molding

tshuab. Cov lus teb sai dua thiab kev tswj xyuas qhov tseeb yog qhov zoo dua.

● Lub vaj huam sib luag yog xim kov lub vijtsam, thiab kev ua haujlwm ntawm lub vijtsam ntshiab yog

ua ke ntau dua.Kev txhawb nqa rau ntau hom lus.

● Lub kaw lus nrog dual-core microprocessors ua rau nws muaj kev kub ceev, tiv thaiv lub suab nrov, kev siv hluav taws xob tsawg.

● USB interface tuaj yeem hloov kho lossis cov txheej txheem thaub qab.

● Internal soj ntsuam Ethernet interface, yooj yim kev twb kev txuas.

● Ntse kev ruaj ntseg nta zoo li nplooj ntawv prompts, Muab cov lus qhia txog kev tu thiab lav.

● Txhaj siab, tshaj tawm, kawg thiab tuav lub siab nkhaus zaub graphical.

● Nrog cov ntaub ntawv 120 pawg thiab 120 pawg los hloov kho lub tswb muaj nuj nqi.

● Khoos phis tawj khau raj ntsuas tus kheej ua haujlwm thiab lub tswb tsis ua haujlwm.

● I / O simulation muaj peev xwm ua kom muaj txiaj ntsig hauv online analog tawm tswv yim thiab cov ntsiab lus tso tawm.

● Txhawb kev saib xyuas ib txhij ntawm ntau lub tshuab los ntawm kev siv lub tshuab computer, cov neeg tswj xyuas tuaj yeem ua tau. txawv raws li cov txheej txheem tsim khoom, kev npaj cov peev txheej tsim khoom.

● Tus neeg siv-phooj ywg tsim layout manipulation.

● Servo drives tuaj yeem ua tiav ntau yam kev tswj hwm ntawm digital tswj thiab analog tswj.

● Ntau qhov kaw-kho saib xyuas cov cuab yeej raws li tus qauv hloov pauv hom hluav taws xob qhov muag, lub qhov muag hluav taws xob ntsuas hluav taws xob, qhov muag hluav taws xob ceev, thiab lwm yam.

4

KOOB HONOR

Phoenix/ES series

● Lub Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hwj Hluav Taws Xob yog lub zog hluav taws xob tag nrho, thiab kev txhaj tshuaj nrawm tuaj yeem ncav cuag 300-1000mm / s;

● Cov khoom khaws cia tau txais cov lus teb siab, tsis tshua muaj inertial servo lub cev muaj zog nrog txoj siv sia log tsav ntsia hlau qauv, Tsis tsuas yog tuaj yeem txhim kho qhov tseeb, tab sis kuj txuag hluav taws xob. Nws tuaj yeem ua tiav kev ua haujlwm sib xyaw ua ke, ua kom luv lub voj voog molding;

● Nrog finite element technical analysis platen tsim, optimizing platen qauv, nplooj siab rau ceev ceev, tshwj xeeb tshaj yog haum rau precision pwm siv;

● Kev siv cov qauv tsim qauv, tib lub pwm xauv lub tshuab tuaj yeem ua ke nrog cov kev sib txawv ntawm cov txheej txheem txhaj tshuaj thiab cov ntsia hlau.

1. peb yog leej twg?

Peb yog ib lub tuam txhab kev lag luam koom ua ke, feem ntau yog rau cov tshuab yas tshuab ib-nres kev pabcuam, thiab tseem muaj kev pabcuam rau cov neeg siv khoom txawv tebchaw hauv Suav teb los muab peb lub Hoobkas tshuaj xyuas thiab tswj cov khoom lag luam.

2. Peb tuaj yeem lav qhov zoo li cas?

Ib txwm ua qauv ua ntej ua ntej ntau lawm; Ib txwm soj ntsuam zaum kawg ua ntej xa khoom;

3.Dab tsi koj tuaj yeem yuav los ntawm peb?

yas recycling tshuab, tshuab moulding tshuab, txhaj tshuab, lej tswj tshuab

4. Vim li cas koj yuav tsum yuav los ntawm peb tsis yog los ntawm lwm tus neeg muag khoom?

yas machinery ib qho kev pabcuam nres, los ntawm kev rov ua dua pelletizer mus rau cov khoom yas zaum kawg, peb muab rau txhua lub tebchaws muaj tus neeg sawv cev rau kev pabcuam tomqab muag, cia cov neeg siv khoom zoo kuaj thiab xav tau. thov txaus siab rau peb yuav muab kev pabcuam sib txawv rau koj, yog tias koj xav tau kuv

5. Peb tuaj yeem muab cov kev pabcuam twg?

Txais Cov Lus Cog Tseg: FOB, CFR, CIF, EXW, DDP;

Txais Nyiaj Them Nyiaj: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

Hom Kev Them Nyiaj: T / T, L / C, D / PD / A, MoneyGram, Credit Card, PayPal, Western Union, Nyiaj Ntsuab, Escrow;

Lus Hais: Lus Askiv, Suav, Mev, Nyiv, Portuguese, German, Arabic, Fabkis, Lavxias, Kauslim, Hindi, Italis

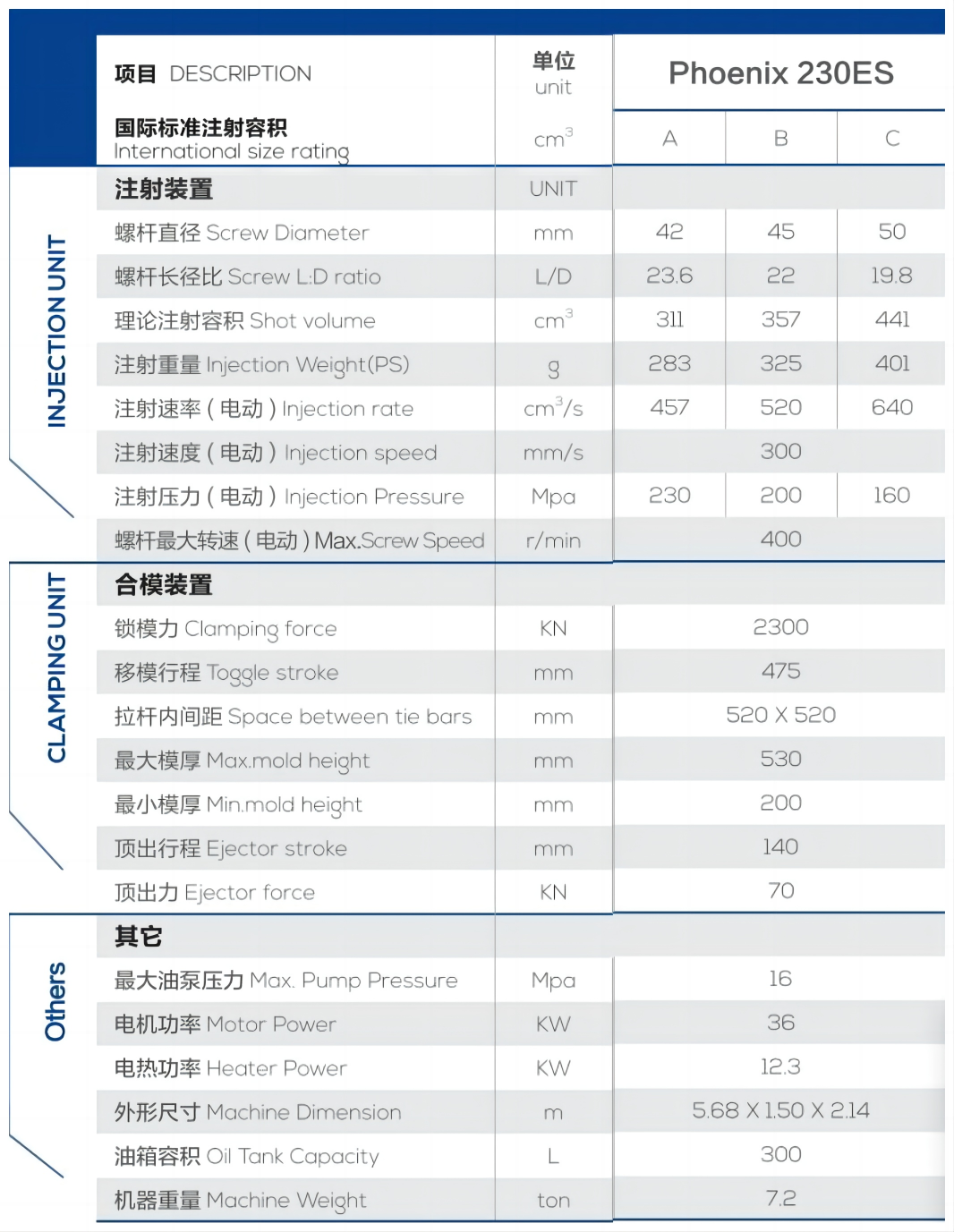

SPECIFICATION

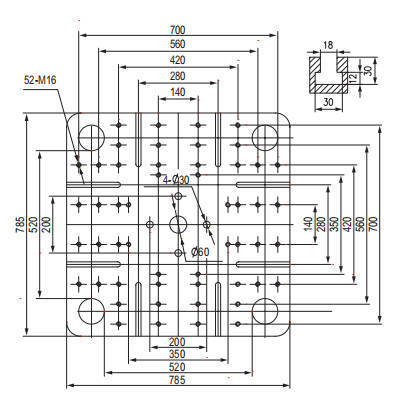

TSEEM CEEB SIZE